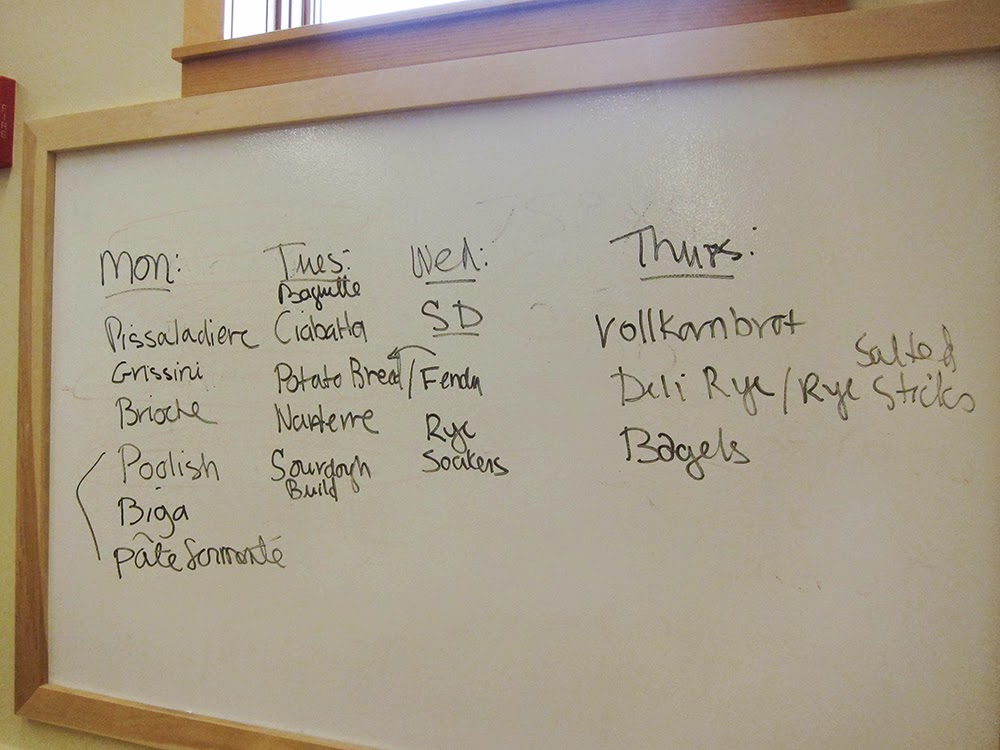

Artisan bread class at King Arthur Flour, Day 4

/On to the finale of the 4 day artisan bread class at King Arthur Flour!

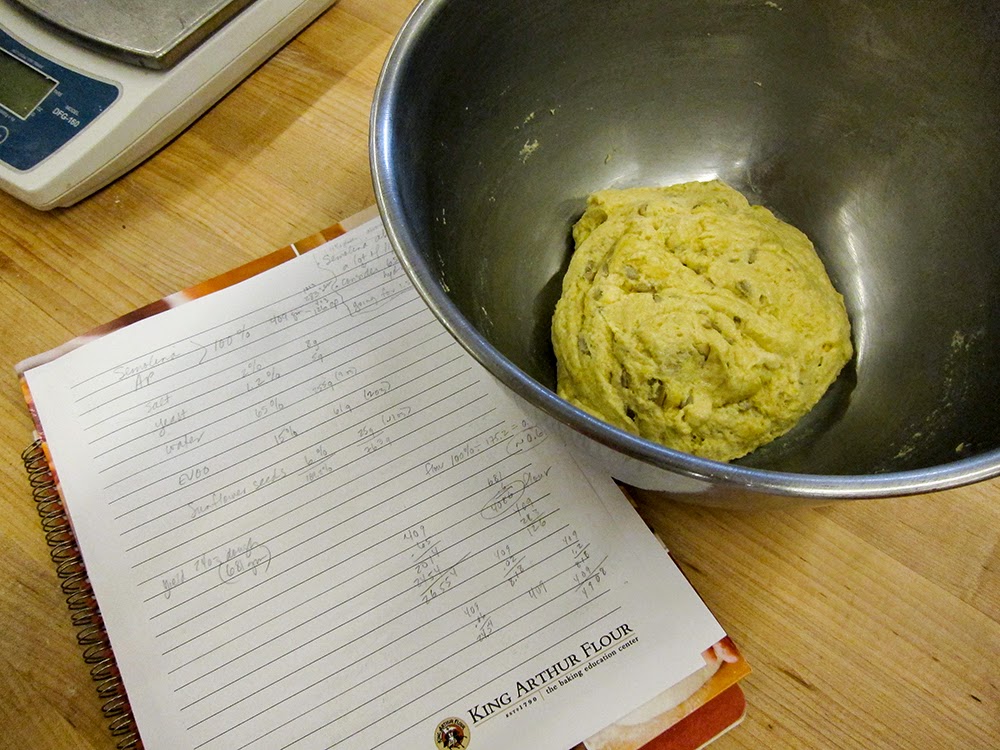

We began the morning by mixing our semolina dough which we had planned the day before as a straight dough, no pre-ferment required.

The dough came to together very nicely and felt great! A good sign.

After folding and a rest - ready to shape:

We shaped a basic batard . . .

and, after a rise, scored it before baking:

And now I must insert a Charley Brown "RATS", for I fear I do not have a photo of the baked semolina!! How sad.

We had some lecture time today as well, specifically focusing on rye and its variables. The approach changes depending on the percentage of rye flour (vs all purpose or whole wheat e.g.) in the dough or whether you use medium or whole rye. Factors such as hydration as well as the proteins, sugars and enzymes in rye play major roles in how the dough is mixed and proofed.

I won't go into all the technical jargon, but suffice it to say, there's a lot to learn about rye! Hey, here's an idea! Take a class at King Arthur!

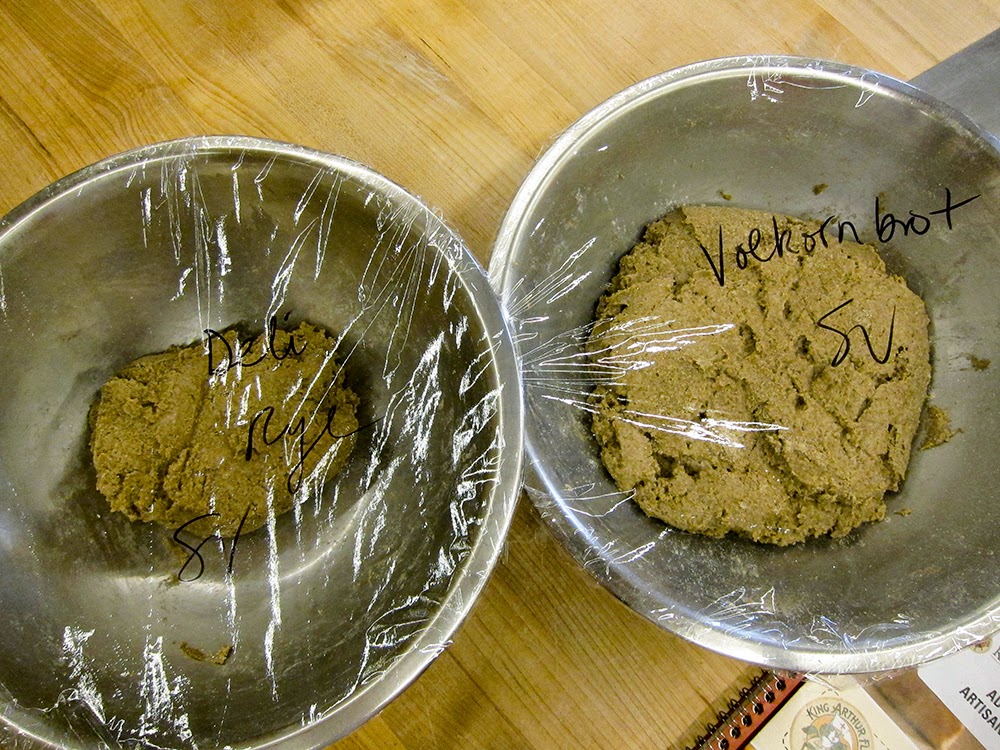

Taking our rye starters that had been sitting overnight at room temperature . . . .

we mixed the deli rye dough, the lighter rye of the two . . . .

and the volkornbrot, a classic German whole rye dough:

Above: all the mixin's for volkornbrot

For the volkornbrot, once all of us had weighed the ingredients into our mixing bowls, our KitchenAids were started in sync so the slow speed, 8-10 minute mixing time would be the same for all. We stopped the mixers a couple of times to scrape down the bowl, then shaped a rectangular loaf, scored it and placed it in a standard loaf pan for baking.

The finished product:

We had the option of shaping loaves or rolls with the deli rye dough. A number of us opted for loaves, and the majority of these were scored with traditional crosswise slashes. We could try other patterns if we wished.

The finished loaves had a lovely browned exterior and a wonderful rye aroma. Notice the scissors snipped pattern on one of my loaves.

Some of the sourdough bread and bagels that had been refrigerated overnight were also baked today, so there were loaves galore sitting around the kitchen.

And then it was time for a tasting!

The semolina is along the left side of the table above. It had a lovely crumb and very nice flavor - a keeper for sure! We were proud of this bread we had created, although many of us felt a bit of sweetening with honey or maple syrup would add just the right balance to this loaf.

Wanda voted for adding cranberries, and Jeff suggested a nice schmear of orange marmalade to garnish a slice.

To top off our terrific 4 day experience we ended with a low-key graduation ceremony. We all received a certificate of completion and a "lovely parting gift" of a bakers couche. Hip hip hooray for bread baking!!

Above: instructors Sharon and Jessica doing the honors

We gathered for a final group shot . . . .

then packed up our goods and said au revoir.

Perfect.